India’s Growing E-Waste Problem: 72% Increase in Just Five Years

The Troubling Rise of Electronic Waste At Namo E-Waste, we’ve been tracking India’s electronic waste situation closely, and the numbers are honestly shocking. According to recent data from the Ministry of Housing and Urban Affairs, India produced about 1.75 million metric tonnes of e-waste last year (2023-24). When you compare that to what was happening five years ago, that’s a 72% jump! India now ranks third globally in e-waste generation, just behind China and the US. What’s particularly concerning to us is that only around 30% of this waste gets properly recycled through official channels. The rest? It’s either handled informally (which often means unsafely) or simply left untreated. If nothing changes, experts believe India could be generating 5 million tonnes annually by 2030. That spells trouble for the environment, public health, and the economy – issues we at Namo E-Waste are committed to addressing. How Bad Has It Gotten? Looking at the yearly breakdown: Financial Year E-Waste Generated (Metric Tonnes) 2019-20 1,014,961 2020-21 1,346,496 2021-22 1,601,155 2022-23 1,609,117 2023-24 1,751,236 The trend is clear and worrying. While India has become a digital powerhouse with over a billion smartphone users (making it the second-biggest smartphone market worldwide), it’s struggling with one of the lowest formal recycling rates among major economies – a gap our company is working to bridge.

How to Recycle Lithium-Ion Batteries to Reduce E-Waste

Lithium-ion batteries power our modern world, from smartphones and laptops to electric vehicles and renewable energy storage systems. But in the same wave of increasing dependence on such energy sources, there also arises an equal concern: what happens once the batteries themselves have reached the end of their lifecycle? Improper disposal of lithium-ion batteries contributes strongly to electronic waste, which poses environmental hazards as well as increased safety risks. Recycling these batteries is a critical step toward reducing e-waste and conserving valuable resources. This blog explores why recycling lithium-ion batteries matters, how the process works, and what individuals and organizations can do to contribute to a sustainable future. Why Recycling Lithium-Ion Batteries is Crucial Lithium-ion contains materials such as lithium, cobalt, nickel, manganese, and graphite, which are limited in reserves. Extracting these materials requires mining, an energy-intensive process, usually damaging ecosystems, contributing to greenhouse gas emissions, and social and ethical concerns in mining communities. Recycling can decrease demand for virgin material and associated environmental impact. Besides, lithium-ion batteries are dangerous if they are sent to the garbage, as they may be prone to catching fire or explosion owing to residual charge. Also, e-waste including the toxic chemicals inside can leach into soil and water, harming both ecosystems and human health. How Lithium-Ion Recycling of Batteries Helps in Reducing E-Waste The problems for which recycling of lithium-ion batteries is relevant include: Resource Recovery: Recoverable metals such as cobalt, nickel, and lithium are recovered and reused in other new batteries or applications. Waste Reduction: Recycling reduces the amount of hazardous materials that end up in landfills or incinerators. Energy Savings: More energy is saved in making new batteries from recycled materials than if raw resources were used. Environmental Protection: Proper recycling ensures toxic substances do not contaminate the environment. The Lithium-Ion Battery Recycling Process Recycling lithium-ion batteries takes more than a few steps. Sorting of useful extractable materials and dangerous materials must be undertaken to the highest safety standards. Collection and Transportation The first step is the collection of used batteries and transportation to the recycling plant. Specialized containers are used to avoid accidents such as short circuits, fires, or leaks during transport. Sorting and Disassembly The facility sorts the batteries by chemistry and size. Lithium-ion batteries differ in type-most are cylindrical cells in construction, commonly found in power tools, while others are pouch cells in smartphones. At some facilities, workers manually disassemble the batteries to separate casings, electrodes, and separators. Pre-Treatment The pre-treatment entails shredding or dismantling the batteries to unveil internal components. In some cases, the batteries freeze to prevent combustion before shredding. Material Recovery The core materials are extracted using chemical, thermal, or mechanical methods. Pyrometallurgy, or High-Temperature Processing: Smelting of batteries to extract metals such as cobalt, nickel, and copper. This method requires huge amounts of energy and may give off emissions. Hydrometallurgy, or Chemical Leaching: Metals are dissolved in a solvent and separated and purified. This is more efficient and less dangerous for the environment. Direct Recycling: This emerging technology preserves the battery’s cathode materials, allowing them to be reused without extensive processing. Refining and Reuse Recovered materials are refined to meet industry standards and sold to manufacturers, often for use in new batteries. Challenges in Lithium-Ion Battery Recycling Despite its benefits, lithium-ion battery recycling faces several challenges: Complexity: Lithium-ion batteries contain multiple materials and chemistries, making it difficult to standardize recycling processes. Economic Feasibility: For any battery containing low cobalt, recycling costs outweigh the value of recovered materials. Collection Infrastructure: Drop-off locations are scarce, and consumers are not informed about where to take or drop off the batteries. Safety Issues: Lack of proper handling during collection or processing could result in fires or chemical exposure. How to Recycle Lithium-Ion Batteries A Step-by-Step Guide to Consumers As a consumer, we can actually help in reducing e-waste by recycling lithium-ion batteries appropriately. Here’s how: Identify Recyclable Batteries Check the product labels or user manuals to identify whether your battery is lithium-ion. Common products include: Smartphones Laptops Power tools Electric vehicles Avoid Improper Disposal Do not dispose of lithium-ion batteries in landfills or regular recycling bins. These may lead to fires or contamination in landfills. Find Recycling Programs Look for collection centers using: Retail stores (many electronics stores accept used batteries). Municipal e-waste collection programs. Companies or websites specialized in battery recycling. Prepare Batteries for Recycling Moisten and tape the terminals to avoid short circuits. Store batteries in a cool, dry place until you drop them off. Spread Awareness Educate friends, family, and colleagues about recycling lithium-ion batteries and share resources that might make the process easier. Corporate Responsibility in Battery Recycling Organizations and producers play a very great role in managing e-waste. There are several things that can be done: Extended Producer Responsibility Under EPR policies, manufacturers are responsible for the end-of-life handling of their products, including their batteries. This involves establishing take-back programs and ensuring proper recycling. Innovation in Design Companies can design batteries to be recyclable, use less toxic materials, and be more easily disassembled. Recycling Infrastructure Investment Investment in recycled infrastructure can support more advanced recycling technologies, including direct recycling, to make the process more efficient and less costly. Partnership with Recyclers An organization could partner with a qualified recycling business that ensures the used lithium ion batteries are sent to them to ensure responsible disposal. Future of Lithium Ion Batteries Recycling The growth in the demand for lithium-ion batteries is accompanied by the need to do so sustainably. All engaged governments, businesses, and consumers must come together to develop a circular economy for their batteries; there should be a continuous reuse of the materials rather than getting them wasted. New technologies being developed include AI-powered sorting systems, direct recycling methods, and re-use applications for batteries to achieve this objective. Conclusion Lithium-ion battery recycling is essential as it will help cut the waste rate of e-wastes; it will help save natural resources and protect the environment. Understanding importance in taking the right action—whether as

Sustainable Corporate Relocation: How Companies Can Go Green While Relocating Offices

Corporate relocations can be exciting yet daunting, from packing and transporting office materials to setting up the new space. That said, with environmental awareness in today’s era, supply chains are not just about efficiency but also sustainability. Companies can take this chance and decrease their footprint on the environment by becoming eco-friendly during such transitions. Here are some ways businesses can make their office relocation sustainable and beneficial to the planet. Why Sustainable Relocation Matters The process of moving an office generates tons of waste, from discarded furniture to e-waste and piles of packing material. Coupled with carbon emissions from transportation, a typical corporate relocation can leave a significant environmental impact. Sustainability-focused relocation can bring value not only to the environment but also to CSR commitment by strengthening a company’s brand image and employee satisfaction. Planning for a Sustainable Move Planning is the foundation of sustainability. Here’s what to do: Sustainability Audit Ahead of time, determine what will be moved, reused, or recycled. Do a thorough inventory of everything that can be: Repurposed in the new office. Donated, perhaps to charity, if furniture and electronics are still usable. Recycled, especially e-waste manage such as old computers and printers. Select a Green Moving Company Partner with environmentally friendly moving companies. Find movers that: Use fuel-efficient vehicles or offset their carbon emissions. Use reusable packing materials like plastic crates, not cardboard boxes. Have a recycling program for unwanted materials. Engage Your Employees Engage your employees in the sustainability mission by organizing initiatives such as: Pre-move donation drives. Workshops on how to pack sustainably. Encourage carpooling or public transport during the relocation process. Reduce Waste During the Move Less Packing Materials: It is one of the biggest contributing sources of waste during relocations. To reduce that: Use reusable boxes and crates instead of cardboard. Wrap items in old newspapers, fabric, or biodegradable packing materials. Avoid using bubble wrap and opt for alternatives like corrugated cardboard or shredded paper. Digital in preference to Physical Digitize as much as possible before the transfer instead of moving mountains of paper documents. Tell employees to digitize essential files and recycle paper-based materials responsibly. Eco-Friendly Office Setup Once transferred to the new location, ensure that sustainability continues in setting up an eco-friendly office: Equipment of the New Office Set up the new office with equipment that guarantees energy efficiency. Use appliances with a viable ENERGY STAR rating to cut down electricity consumption. Green furniture, not Use refurbished furniture. Purchase second-hand or upcycled furniture. Buy from firms that use sustainable furniture manufacturing practices. Energy-Efficient Layout When designing the office layout, try to make as much of it open with access to as much natural light as possible. Try to keep the air flowing, allowing minimal need for extra heating or cooling by using open layouts. Green Transportation Solutions Reduce Trips Reduce the number of trips during the move by consolidating items into fewer shipments. This not only cuts costs but also lowers carbon emissions. Offset Carbon Emissions If transportation is unavoidable, consider working with services that offer carbon offset programs. These programs fund renewable energy projects to neutralize the environmental impact of your move. Handling E-Waste Responsibly One of the biggest issues with corporate relocations is related to e-waste, such as computers, printers, and cables, that are abandoned without care. E-waste can cause harmful materials to leak into the environment if not disposed of properly. E-Waste Management Best Practices Evaluate Appeal: Find out whether the old electronics can be repaired, upgraded, or donated. Recycle Responsibly: Find registered e-waste recycling companies that have ethical recycling practices. Safe Data: Erase all data off devices before recycling or donating. Involve Employees in the Sustainability Process: The moving process is an excellent time to develop a culture of sustainability among employees. Advantages of a Green Office Relocation Successful implementation of an eco-friendly relocation practice has several benefits, which include: Cost Savings Implementing sustainability is often compatible with cost-effectiveness. Reusing materials and minimizing waste cuts operational costs for a company. Brand Reputation Customers and the workforce now tend to favor companies that value sustainability. A green move cements a company’s commitment to environmental responsibility. Sustainable Result Eco-friendly practices implemented during relocation will set the stage for the new office to be more sustainable in the long term. Case in point: Green relocation in action: One inspiring example is tech giant Dell, which has sustainability throughout its efforts, including in-office moves. It reuses old furniture, has digital instead of paper records, and hires green movers. All these show how companies can change the game on their own while keeping their green footprint small. Conclusion: A Greener Move, A Brighter Future Sustainable corporate relocation is not only a trend of today but an essential requirement for companies in today’s world. From reducing waste and proper management of e-waste to optimizing the transportation system and establishing energy-efficient offices, companies have very many avenues to contribute positively to the environment. Eco-friendly practices in relocations benefit businesses by saving the planet, increasing their brand reputation, and encouraging employees to develop the same habits for a better future. A green move relates not only to the journey to a new office but to paving the way for a more sustainable future. Do you have an office move in the pipeline? Do it green and set an example for others to do the same.

E-Waste Legislation: How Global Policies Are Shaping the Future of Recycling

In a world where the average smartphone is replaced every 2.5 years, electronic waste is one of the biggest environmental challenges our generation faces. Generating over 50 million metric tonnes of e-waste annually, or roughly equivalent to throwing away 1,000 laptops every second, is as important as it ever has been for solid legislative frameworks. At Namo E-waste, we are focused on the sustainable way of e-waste management. In this blog, we’ll try to bring forth how the legislation at global levels for e-waste is bringing influence through effective recycling through real-life examples showing its effective implementations. Evolving Landscape of E-Waste Legislation It started in the shadows of unregulated practices of disposal. In the 1990s and early 2000s, thousands of shipping containers were overflowing with old electronics exported from developed nations to dangerous disposal sites in developing countries Communities in places such as Guiyu in China became infamous for their toxic “electronic graveyards.” Such harsh conditions called for a new world consciousness. E-waste was multiplying exponentially, and governments and agencies now needed to step into action. This activism marked the beginning of a new era in environmental law. Role of legislation in e-Waste management is crucial. Major Global Policies and Their Impact The WEEE Directive: Europe Leads the Way The EU’s Waste Electrical and Electronic Equipment Directive, introduced in 2003 and modified in 2012, is now the international standard for e-waste legislation. It requires the original producers and also the importers to take responsibility for their products-from origin to end-of-life treatment and recycling. Purpose and Objectives: This directive encourages the reuse and recycling of e-waste along with its recovery so that the environmental effect of this waste is reduced. Scope of Products Covered: It ranges from domestic equipment to information technology hardware and covers a wide range of electronic products. Compliance Requirements: The compliance requirements specify that manufacturers and retailers have to be registered, meeting the level of recycling levels set plus information regarding disposal. Under WEEE, the collecting member country has to collect 65% of all e-waste sold or 85% of e-waste generated. Such a stern target placed aggressive pressure on innovators, making them push innovation into the design of products and recycling technologies. By 2022, millions of tonnes of e-waste recycled properly, and highly valuable materials recovered in and across billions of euros. The Basel Convention: Global Protection The other benchmark of international e-waste governance is the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal. It was adopted on March 22, 1989, in Basel, Switzerland, and came into force on May 5, 1992. It had an amendment in 2019, which emphasized electronic waste and banned hazardous electronic waste from being exported from developed to developing countries. Overview and Objectives: The Convention aims at protecting human health and the environment from the harmful effects of hazardous wastes. International Trade Restrictions: The export of hazardous e-waste should not be exported from developed countries to underdeveloped countries without prior informed consent. Corporate Compliance: Leading by Example Dell’s Sustainable Cycle Dell Technologies explains how businesses may succeed in controlled electronic waste environments. Since 2007, the business has recycled more than 2.5 billion pounds of electronics as part of its global recycling effort in response to the WEEE Directive. The company’s innovative strategy includes the application of principles of design for recyclability in new products, free recycling services given to customers worldwide, the use of recycled materials in manufacturing new products, and a blockchain-based tracking mechanism for all the recycled materials. Samsung’s Green Shift Samsung’s Galaxy Upcycling initiative defines how legislation sparks innovation. Under the initiative, the old smartphones are converted to IoT devices that are extended back into lives and not into e-waste. Since 2021, the company has recycled around 5 million smartphones from landfills and also reduced manufacturing carbon emissions by 20%. Environmental and Economic Impacts The implementation of e-waste laws has shown significant advantages. Recent studies have shown that: Toxic electronic components reaching landfills are reduced by 40%. $14 billion worth of precious metals are recovered annually. 3 million new employment opportunities in the recycling industry. 15% reduced raw material mining for electronics. The economic opportunities have been tremendous too. The global e-waste recycling industry is to take the lead by growing to about $143.7 billion by 2028, channeled by regulatory compliance and the possibility of recovery resources. The Complexities of E-Waste Legislation Despite these advances, many problems exist that prevent the effective execution of e-waste regulation, such as: Lack of Awareness: Most consumers are uninformed about the impact of e-waste on the environment and its importance in safe disposal. Diverse Standards: The lack of standards throughout the countries, hence inducing undue difficulties for producers as well as retailers while in the process of ensuring conformity. Challenges to Small Businesses: It brings immense financial and logistical pressures on small businesses. The Future of E-Waste Recycling The future of e-waste legislation suggests the need for coordination and complexity. Some emerging trends include AI-driven recycling systems that enhance material recovery, tracking an electronic product on a blockchain and It would be through collective action from governments, businesses, and consumers that an improved e-waste management practice would take place in order to make a clean and healthy planet remain for successive generations. Conclusion In conclusion, e-waste legislation is the future of recycling. The legislation encourages observance and healthy patterns that will help in reducing impacts brought about by environmental waste from electronics. At Namo E-waste, we invite you into our fold to view responsible ways of dealing with e-waste. Together, let’s influence responsible recycling practices within our communities and bring ourselves a better future. Let’s act today to protect our planet!

The Journey of eWaste: From Your Home to Recycling Plant: A Step-by-Step Guide

The world today is heavily reliant on electronic devices. While being digitally connected has made life easy, rapid consumption of these electronics has given rise to an alarming level of waste, popularly known as electronics. In the year 2019, approximately 62 million tonnes of e-garbage were generated across the globe, and this number is expected to grow as suggested by Global E-waste Monitor 2024. Unfortunately, part of this e-waste ends up in landfills and causes more harm to the environment and human health. On the brighter side, however, e-waste can be recycled and valuable materials can be extracted from it, hence reducing the environmental burden. In this blog post, we will take you through the journey of e-waste, from when it leaves your home to when it finally gets processed and repurposed in a recycling plant. So, in this step-by-step guide, we’ll talk about how e-waste management companies, like Namo eWaste in India, really play a great role in this critical process. Step 1: Collection – The First Step in eWaste Recycling The journey of electronic waste recycling begins when you end up throwing away a broken phone, an outdated computer, or an obsolete TV. Collection methods vary, but can include drop-off points and direct collection services offered by companies that recycle e-waste. Many cities or recycling centers have designated drop-off points for old electronics, while some companies specialize in door-to-door collection services of old electronics directly from consumers. Take-back programs for the manufacturer: Many electronics manufacturers have take-back programs where they accept their old products for recycling. Step 2: Transportation – From getting eWaste to Recycling Facilities Once collected, the e-waste is transported to specialized recycling facilities. In this step, logistics and proper handling come into play since some of the devices contain hazardous materials like lead, mercury, or cadmium, which are harmful to the environment if not treated properly. Companies like Namo eWaste utilize specific vehicle capacities designed to carry e-waste to recycling plants without contaminating in transit. Step 3: Sorting and Dismantling – Removing the Constituents On-site at the recycling facility, the actual process follows: The e-waste will be sorted and dismantled. This includes; Manual dismantling: The human personnel demolishes electronic products, breaking down constituents such as circuit boards, wires, plastics, metals, and glass. Sorting by category: Items will be sorted out according to the type of material, for instance, metals, plastics, and hazardous elements like batteries or fluorescent lights. Step 4: Shredding and Preprocessing – Breaking Down the Waste As the casing is ripped apart, the electronic components are torn into smaller pieces to be further processed. Shredding is required for breaking huge electronics like monitors or computers into accessible sizes. Beyond that, shredding helps sort easily and prevents the reuse of personal data gathered on hard drives and other storage gadgets. Step 5: Material Recovery – Valuable Resources Extraction The primary aim of e-waste recycling is the recovery of useful materials. E-waste, for example, holds metals like gold, silver, and copper that are recovered and reused in new products. The process includes: Magnetic separation: This aids in the recovery of ferrous metal like iron and steel. Eddy current separation: This separates non-ferrous metal, such as aluminum, from other residues. Hydrometallurgical and pyrometallurgical processes: the processes extract precious metals, such as gold and silver, from circuit boards and other components. For example, Namo eWaste has a well-solidified process of recovering precious metals but rare earth elements as well that are used for manufacturing current electronics. They utilize environmentally safe methods of minimizing energy intake to reduce pollution while extracting. Step 6: Hazardous Waste Handling-Safe Disposal of Hazardous Materials Most of the electronic wastes usually come with dangerous materials that include mercury, lead, and cadmium. In case they get improperly disposed of, they may lead to severe health complications. During recycling, these toxic materials are separated and taken to waste facilities identified as hazardous. For instance, the old televisions and monitors contain cathode ray tubes. These include substantial proportions of lead and must be carefully dealt with while disposing of them. Step 7: Repurposing – Giving New Life to Recycled Materials Examples of this include when valuable materials are first extracted from the materials, and they are recycled and fed back into the cycle of production. Recovered metals, such as copper and gold, can be reutilized to create new electronic parts, while plastics can simply be melted down and reformed into new products. For example, recycled gold recovered from old circuit boards may eventually find its way into new smartphones or computers. The plastics recovered might be turned into the production of new electronic casings or household items. Recycling e-waste benefits the companies involved by reducing mining and extraction of raw materials necessary for production, hence conserving natural resources. Step 8: Global eWaste Management Strategies – The Good, the Bad, and the Ugly The countries of the world are struggling to effectively address the problem of e-waste without a common strategy to manage this growing evil. There have been various strategies so far: Extended Producer Responsibility: Countries in the European Union have EPR laws that make manufacturers responsible for the disposal and recycling of their products in proper ways. Deposit-refund schemes and buy-back programs for old electronics – Consumers are motivated to return the old electronics. As is witnessed in countries such as Japan and South Korea. Public Awareness Campaigns: Companies like Namo eWaste have also conducted similar awareness campaigns for consumers in India so that people may realize the importance of recycling e-waste and may adopt correct habits of responsible use and disposal. And even though these strategies have proved to work, there’s so much work that needs to be done in developing countries, where their handling of e-waste is unprofessional and improper. The organizations and the governments will continue to come together to find a sustainable solution. Conclusion: Thus, the journey from your house to a recycling plant is a comprehensive one and a vital process for reducing the environmental footprint of spent electronics.

The Hidden Dangers of eWaste: How Toxic Components Impact the Environment and Human Health

Defining E-Waste In our modern, advanced, and technological world, electronic waste or eWaste has emerged as one of the fastest-growing waste streams all over the planet. These technological advancements themselves provoke more frequent purchases of electronic devices. This opens many valves in the flow for an increasing volume of discarded electronics. People love using modern gadgets that provide them with significant comfort, and thus, this has a massive dangerous impact on the environment and human health since hazardous materials in the eWaste can leak into ecosystems when left unattended for long. What Makes E-Waste Toxic? E-waste recycling includes old electronic equipment such as computers, cell phones, televisions, and consumer electronics. While most of them reach the end of their life cycle, the majority of them find their way into landfills or get processed through recycled channels that are unsuitable for handling them. However, it is not the amount of eWaste disposed as much as it is about the toxic nature of the materials they contain. Some of the most prominent toxic substances found in eWaste are lead, mercury, cadmium, and brominated flame retardants. Lead: Lead is found in cathode ray tubes (CRTs) and solder in circuit boards. It is very harmful; a health concern at even low exposure levels. Since eWaste contains lead, the soil and water can be contaminated due to its leaching. Prolonged exposure to lead can lead to serious neuro disabilities, significant developmental problems in children, and other health problems for adults. Mercury: Mercury is widely utilized in flat-screen displays, and also in batteries. Its toxic effects are highly disturbing because mercury has a tendency to bioaccumulate and find its way through the food chain affecting aquatic life, including health and gastrointestinal anomalies within the people who consume contaminated fish and livestock. Exposure at high levels may cause severe neurological and developmental disorders, especially among children and pregnant women. Cadmium: Cadmium commonly occurs in nickel-cadmium batteries and certain circuit boards. Like lead and mercury, cadmium is toxic to human beings and the environment. In the soil or water environment, cadmium causes accumulated toxicity in the food chain in plants and animals. At long exposures, cadmium causes kidney damage, bone fragility, and respiratory problems. Brominated Flame Retardants (BFRs): Persistent organic pollutants, BFRs, are applied in a number of electronics with the aim of reducing flammability. They have a tendency to leak into the environment when disposed of or incinerated improperly, causing harm to human health as well as wildlife. BFRs have been linked with endocrine disruption, neurodevelopmental disorders, and cancer. Environmental Impact of Improper eWaste Disposal If not disposed of properly, toxic components from eWaste could leak into the environment, and the effects reflect on both ecosystems and human health. Landfills become hazardous environments because they are often overloaded with electronic devices. Rainwater seeps chemical pollutants from eWaste into the soil and groundwaters, making it possible to contaminate the soils and drinking water sources. This may lead to adverse destruction for local ecosystems, affecting plants and wild animals. Another significant hazard is presented by incineration, which exposes soil and water to contamination. Incineration of eWaste disperses toxic fumes and particles in the air, resulting in air pollution and other health conditions among the people. The consequences of these dangerous effluents also spread to distant communities, thereby spreading pollution globally. Health Risks for Humans The hazards associated with health from the exposure of eWaste pose alarming concerns. Hazardous material is mainly exposed to workers in informal sectors, mostly from underdeveloped or developing nations, having minimum to no access to protective measures during improper disposal and recycling. Lead poisoning, respiratory problems, and more serious health issues are probable by such individuals. Overall Global eWaste Management Strategies Due to the harmful effects of eWaste, the governments along with other related agencies worldwide have initiated several measures to deal with the issue effectively. Among such methods, an important aspect includes a set of rules and regulations involving proper waste disposal and recycling of electronic waste. Extended Producer Responsibility: The EPR policies hold the manufacturers responsible for the entire lifecycle of the product, from the start to its end, also including the product disposal phase. EPR would make the producers design for recyclability, leading to less eWaste being produced and fostering responsible disposal methods of the products. Recycling Programs: The creation of eWaste recycling programs by many countries ensures that electronic devices are processed safely. Such programs involve collecting, sorting, and processing eWaste to recover the value of material but ensure hazardous components are disposed of safely. Effective recycling can highly minimize the effects brought about on the environment by eWaste. Public Awareness Campaigns: The second element is awareness of the dangers of eWaste and its proper disposal needs. Education awareness can teach the customers different options for recycling, should make them think twice before throwing away electronic goods, and instill a sustainability culture. International Cooperation: Since the issue of eWaste is international, international cooperation should be established. International agreements such as the Basel Convention are established to control and regulate the transboundary movement of hazardous waste, including eWaste, promoting environmentally sound disposal worldwide. Conclusion As concluded, with e-waste comes toxic components that pose significant dangers to the environment and also human health, including lead, mercury, and cadmium among many others. The proliferation of electronic devices makes responsible disposal and recycling very urgent. Effective management of eWaste through awareness, educational campaigns, and cooperation at the international level can help mitigate these dangers posed by electronic waste. Thus, people, businesses, and governments must work together to deliver a healthier future for our planet and its inhabitants. Through such collective efforts, we are able to gain the tide on eWaste while saving our environment and the quality of our health for many generations to come.

How to Destroy Old Business Hard Drives Safely: Tips, Facts, & Importance

Do you know what happens to your old antique business hard drives? Chances are that if you are like most people, then you just throw them out like regular trash. But do you know that this can pose a considerable security threat? An old hard drive has business, personal data, correspondence, documentation, photos, videos, and other stuff that can be used by a third party to deceive you and take control of your digital identity. That is why it is advisable to delete them with security to avoid misuse of the information. In this blog post, you’ll learn the details of hard drive destruction, when to do it properly, and the ways to do it. The Importance of Secure Hard Drive Destruction Data Security: When old hard drives are thrown away, they are not destroyed, and this exposes the business to information technology theft. Erasing files or using a data wiping method does not delete files; it merely conceals them. This information can be retrieved by cybercriminals, hence posing a security threat. The National Cyber Security Alliance supports the data revealing that 60% of small businesses suffer closure within six months of a cyberattack and that discarded hard drives are often vulnerable. Legal Implications: Governments and regulatory organizations demand higher levels of data protection legislation, such as GDPR for the EU member countries or HIPAA for the United States. It also applies these laws that require that personal data should be protected and disposed of when the data is not necessary, and the process should also be secure. The law also provided that any failure to observe all the provisions of the law is punishable by stiff fines. Environmental Impact: Apart from security and legal implications, improper disposal of hard drives is a major reason for e-waste. The Global E-waste Monitor 2020 revealed that 6 million metric tons of e-waste were produced in 2019 and predicted to rise to 74 million metric tons by 2030. Hard drives are composed of dangerous elements like lead, mercury, and cadmium that, when disposed of in landfills, pollute the soil and water systems. Hard Drive Disposal: Separating Fact from Fiction Myth 1: Deleting Files Removes Data Permanently. Fact: When you delete a file, the data does not disappear from your hard drive. Rather, the operating system simply marks that space as free to use for new information; the original data thus stays intact and can easily be recovered using recovery software. In fact, according to a report from Blancco Technology Group, nearly 40 % of second-hand drives purchased online retained recoverable data, showing how vulnerable deleted files are. Myth 2: Physical destruction is not essential if software wiping has been performed. Fact: Software wiping is effective, but it can’t be strictly relied on, especially for modern SSDs. Physical destruction methods, such as shredding or crushing, are more conclusive in the deletion of data. A study from Vanson Bourne recently found that 40 percent of IT professionals still recommend using both software wiping and physical destruction to ensure the best outcome in hard drive destruction. Techniques for Deletion of Old Business Hard Drives There are many ways of ensuring destruction on hard drives, safely and securely. Here are some reliable techniques: Data Wipe by Professional Wipe Tools Data wiping entails overwriting the hard drive’s contents with random data repeatedly, rendering the original information significantly more difficult to retrieve. Commonly utilized tools, such as DBAN (Darik’s Boot and Nuke), facilitate this process; however, this approach is not infallible, particularly when it comes to contemporary SSDs that demand specialized wiping techniques. For absolute reassurance, businesses ought to contemplate pairing this method with physical destruction. Degaussing This employs a very strong magnetic field that would interfere with the information stored on a hard drive and render it unreadable. This works particularly well for traditional HDDs (hard disk drives) but does not work with SSDs (solid-state drives) due to the different nature of the storage technology. Also, drives degaussed are normally unusable afterward. Partnering with Certified E-Waste Recycling Providers Certified e-waste recyclers, including Namo Ewaste, offer secure hard drive destruction. They ensure the hard drives are either physically destroyed or wiped clean before recycling in an environmentally responsible manner. Conclusion Safely destroying old business hard drives is crucial for safeguarding sensitive data, adhering to legal requirements, and reducing environmental impact. There are various effective methods available, from shredding to degaussing, that ensure complete data destruction. Yet, collaborating with a certified provider such as Namo Ewaste offers the assurance of secure, responsible, and eco-friendly disposal of your outdated hard drives.

The Role of Legislation in E-Waste Management: A Global Perspective

In our increasingly digitized world, electronic devices have become an integral part of our daily lives. However, technological advancements have led to a surge in discarded electronics, commonly known as e-waste. This growing problem poses significant environmental and health risks due to the toxic materials contained within these devices. Effective e-waste management strategies and robust regulations are essential to mitigate the negative impacts of e-waste. This blog will explore how various countries have implemented e-waste laws to address this pressing issue and how companies like Namo E-Waste are playing a pivotal role in driving sustainable solutions. The Escalating Challenge of Electronic Waste E-waste is the term used for unwanted electrical or electronic gadgets. It is also frequently called waste electrical and electronic equipment (WEEE) or end-of-life electronics. This encompasses a variety of items, such as refrigerators, washing machines, computers, smartphones, and televisions, used both at home and personally. The problem of electronic waste is growing to a great extent. According to the Global E-trash Monitor, the world generated around 60 million tons of electronic waste in 2020, with a 21% increase expected by 2030. The incorrect disposal of e-waste causes significant environmental dangers since it contains dangerous substances such as lead, mercury, and cadmium, which can leach into soil and water and cause long-term harm to ecosystems. The challenge lies not only in the huge volume of e-waste but also in the complexity of e-waste management and its safe collection, recycling, and disposal. Global Legislative Framework for E-Waste Management Dealing with the e-waste problem and sound e-waste management necessitate strong legal structures on both the domestic and global scales. Although different international treaties and agreements have been created, how these laws are put into practice and upheld can vary between countries and regions. Key International Treaties and Agreements Basel Convention: This treaty regulates the transfer of harmful waste substances. The goal of this agreement is to protect the environment as well as people from the negative impacts of generating, managing, transporting, and disposing of these waste materials. The convention has 170 member countries known as parties. Stockholm Convention: This convention addresses dangerous substances contained in electronic gadgets, such as PCBs and BFRs, which are referred to as persistent organic pollutants. Its purpose is to reduce or restrict the production and use of these harmful compounds. Rotterdam Convention: This is an international environmental agreement that encourages the exchange of information concerning compounds that endanger human health or the environment. It includes standards for the prior informed consent process, which requires countries to be informed about the hazards ahead of time and have granted their consent. Regional and National Legislation Apart from global treaties, numerous nations and areas have established their laws regarding effective e-waste management. These regulations frequently encompass: Producer Responsibility: Manufacturers are required to take responsibility for the disposal of their products at the end of their lives, which includes electronic waste. This may include establishing collection methods, recycling plants, and funding disposal expenses. Extended Producer Responsibility (EPR): It is a regulation that requires manufacturers and importers to handle the disposal and recycling of their products. This signifies that companies have a legal duty to reclaim their products once they are no longer in use and guarantee they are disposed of in an environmentally conscious manner. Waste Management Regulation: It consists of the regulations and guidelines that control how different types of waste are handled, stored, and disposed of properly. This set of rules is designed to safeguard the health of the public and the environment through proper e-waste management as well as handling. Exemplary E-Waste Management Legislation: Case Studies Many countries have shown effectiveness in handling electronic waste by implementing strong laws and creative methods. Germany is frequently referred to as an example of good e-waste disposal practices. The Recycling Management Act in the country enforces a circular economy by mandating manufacturers to reclaim their products once they reach the end of their lifespan. Germany has efficient systems in place for gathering and reusing electronic waste, leading to increased rates of recycling and minimizing the environmental effects of old electronics. In Japan, consumers are required by the Home Appliance Recycling Law to pay a recycling fee when buying new electronics, which finances the appropriate disposal of old items. This system, along with the country’s strict product stewardship rules, has resulted in notable decreases in electronic waste and higher rates of recycling. Challenges and Criticisms of E-Waste Legislation E-waste management encounters major obstacles caused by insufficient laws, varying regulations worldwide, and a lack of enforcement. Even with 53.6 million metric tons of electronic waste produced worldwide in 2019, just 17.4% was properly gathered and processed. The U.S. has a variety of state laws, which create inefficiencies. Developing countries face challenges with importing electronic waste, worsening environmental and health hazards. To address the escalating e-waste crisis, effective management necessitates coordinated global legislation, improved infrastructure, and heightened public consciousness. A Sustainable Future for E-Waste with NAMO eWaste Namo eWaste is revolutionizing e-waste management by following strict laws and utilizing advanced recycling techniques. Our forward-thinking method helps to close gaps in worldwide e-waste regulations and increases public knowledge, establishing a standard in the field. Through promoting innovation and adhering to regulations, Namo eWaste is not just keeping up with current e-waste management guidelines but also influencing a sustainable future for electronic waste.

How Can Businesses Implement Effective E-Waste Management Strategies?

In the digital age, businesses rely largely on technological gadgets. From computers and smartphones to office equipment and servers, drives activities in a variety of businesses. However, as these devices reach the end of their useful life, they contribute to a rising environmental issue: e-waste. The improper disposal of electronic waste endangers the environment, and businesses play an important role in adopting an effective e-waste management strategy. This blog will look at how organizations may opt for sustainable e-waste management and the impact of e-waste, using insights from Namo E-waste, a leader in sustainable e-waste solutions. E-Waste: A Growing Threat to Our Planet E-waste includes abandoned electronic items such as computers, laptops, televisions, and household appliances. These are a concern to the environment because they emit chemicals like mercury, lead, and cadmium, which contaminate the air, water, and soil, causing major health problems for humans and wildlife. For businesses, the impact of e-waste is twofold. Not only do companies generate significant volumes of e-waste as they upgrade or replace equipment, but they also have a responsibility to ensure that this waste is managed in an environmentally friendly manner. Addressing e-waste is crucial for reducing environmental harm and fostering a sustainable future. Why Effective E-Waste Management Matters for Businesses E-waste management is a lot more than merely an environmental concern; with the digital dependency on gadgets, it has been turning into a significant global and economic challenge as well. As technology advances, the life of electronic devices shortens, and the volume of e-waste rises continuously. Effective e-waste management strategies are vital for businesses to mitigate environmental risks, improve their brand image, and achieve sustainable operations. Regulatory Compliance: Many countries have rigorous rules in place for e-waste disposal. Failure to comply might result in significant fines and legal ramifications. Implementing an e-waste management strategy assures compliance with these requirements and avoids potential legal implications. Corporate Responsibility: Companies are increasingly being held accountable for their environmental impact. Sustainable e-waste management improves a company’s reputation as a good corporate citizen, aligns with sustainability objectives, and appeals to environmentally sensitive customers and stakeholders. Cost savings: Sustainable e-waste management can lead to cost savings. Recycling and reusing electronic components can reduce disposal costs and potentially recover valuable materials. Additionally, businesses can avoid fines associated with non-compliance, which can be significant. Creating an E-Waste Management Strategy Evaluate existing E-Waste Practices: Begin by conducting an audit to determine the amount and types of e-waste produced by your company. Identify gaps in present procedures and potential areas for improvement. This assessment establishes a baseline against which to monitor progress and make informed decisions. Setting Clear E-waste Management Goals: Set specific targets for your e-waste management program. What do you hope to achieve? Some common goals include minimizing e-waste, increasing recycling rates, and complying with relevant regulations. Implement Efficient E-Waste Collection Systems: Create internal systems for collecting and categorizing electronic waste. Set up dedicated collecting points inside your business and make them easily accessible. Provide employees with instructions on how to properly dispose of electronic goods and use collection methods. Partner with Certified E-Waste Recyclers: Collaborate with certified e-waste recyclers, such as Namo E-Waste, to ensure that your electronic trash is treated securely and properly. Certified recyclers follow industry best practices and comply with legislation, giving you peace of mind that your e-waste is being properly processed. Best Practices for E-Waste Disposal and Recycling Effective e-waste disposal and recycling are critical to reducing environmental impacts and increasing resource recovery. Here’s how you can do it: Choose Certified Recyclers: Work with trustworthy recyclers who follow strict environmental guidelines. Data Security: Make certain that sensitive data is safely wiped or destroyed before recycling. Material Recovery: Focus on recovering valuable materials like precious metals and rare earth elements. Reduce, Reuse, and Recycle: Prioritize trash reduction and equipment reuse over recycling. Regular Monitoring and Reporting:Track and report e-waste volumes and disposal procedures regularly. Monitoring assists in determining the efficacy of your e-waste management strategy and making any changes. Reporting also indicates your organization’s dedication to sustainability and compliance. Improving and Repairing Equipment: Instead of continually replacing equipment, consider repairing or improving it to extend its life. This method minimizes the quantity of e-waste generated and may be more cost-effective in the long term. By implementing these steps and partnering with a reputable E-Waste management service, like Namo E-waste, businesses can fulfill their environmental duties and also gain a competitive advantage. Leveraging Technology and Innovation Technological improvements have a tremendous impact on improving e-waste management. Advanced recycling technology and customized software solutions can increase efficiency and effectiveness. Namo E-waste blends cutting-edge technology into its services, offering organizations cutting-edge solutions for e-waste management. Businesses that leverage these technologies can remain ahead of regulatory obligations while also contributing to a more sustainable future. Take Charge of Your E-Waste Today! In conclusion, E-waste is no longer a mere byproduct of progress but a complex challenge demanding innovative solutions. By understanding the environmental and economic implications, businesses can transform e-waste from a liability into a strategic asset. Through comprehensive audits, robust policies, and strategic partnerships, organizations can effectively manage their e-waste footprint. Embracing technology and prioritizing recycling are pivotal steps towards a sustainable future. Namo E-waste stands as a committed partner in this journey, as we are a pioneering effort to focus on responsible e-waste management by providing effective and eco-friendly solutions and offering expert guidance and services to help businesses achieve their e-waste management goals. Together, we can build a cleaner, greener tomorrow.

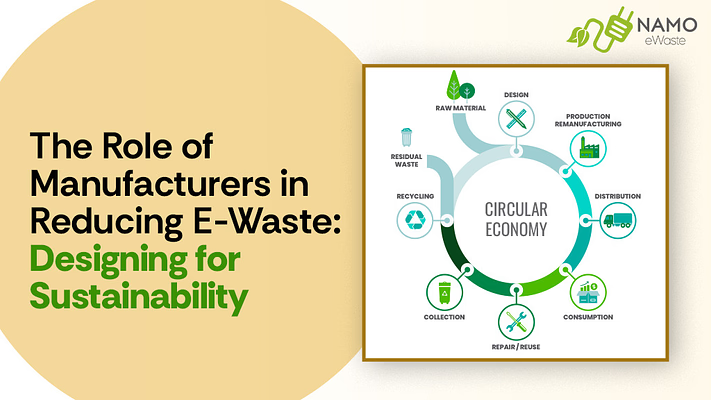

The Role of Manufacturers in Reducing E-Waste: Designing for Sustainability

Image Source: Global E-Waste Monitor 2024 The ever-growing mountain of discarded electronics, known as e-waste, presents a formidable challenge to our planet’s health. In 2019 alone, the world generated a staggering 53.6 million metric tons of e-waste, enough to fill 4,500 Olympic-sized swimming pools. This alarming trend underscores the urgent need for sustainable solutions. While consumers play a role in responsible disposal, manufacturers hold a pivotal position in addressing the e-waste crisis by adopting sustainable product design and responsible manufacturing practices. Why the E-Waste Crisis Needs Affirmative Action Each year, the world generates over 50 million metric tons of e-waste – a figure that’s projected to double by 2050 if left unchecked. This discarded electronic equipment, laden with hazardous materials like lead, mercury, and cadmium, poses a grave threat to our ecosystems and public health. While consumers certainly have a role to play in responsible e-waste disposal, manufacturers are equally, if not more, responsible for addressing this crisis. It’s not just about complying with regulations; it’s about embracing sustainable product design and responsible manufacturing practices that prioritise longevity, repairability, and recyclability. It’s about creating a circular economy where electronic devices have a longer lifespan and minimal environmental impact. Image Source: Global E-Waste Monitor 2024 The Power of Sustainable Design and Manufacturing Source: Research Gate The journey of an electronic device begins long before it reaches the consumer’s hands. From the drawing board to the assembly line, manufacturers have the power to influence a product’s environmental impact. By embracing sustainable design and manufacturing principles, they can drastically reduce e-waste and contribute to a circular economy. Product Design for Durability: Built to Last One of the most effective ways to combat e-waste is to design products that are built to last. By prioritising durability and longevity, manufacturers can extend the lifespan of electronic devices, reducing the frequency of replacements and the amount of e-waste generated. Several design characteristics can improve product durability. Modular Design: Enables easy repair and replacement of individual components, increasing the product’s life. Robust Materials: Using high-quality, robust materials assures that the product will survive wear and tear. Software upgrades: Providing frequent software upgrades can help older devices remain functional and relevant for longer. There are numerous advantages to designing long-lasting products. Reduced E-Waste: Fewer devices discarded prematurely results in less e-waste in landfills. Resource Conservation: Longer product lifespans reduce the need for fresh raw materials, lowering the environmental effect of extraction and manufacturing. Consumer Cost Savings: Investing in durable items can save consumers money in the long run by reducing the frequency with which they must replace their equipment. Examples of durable design features include: Standardised components for easier replacement User-replaceable batteries Software updates to extend product lifespan Clear repair manuals and accessible spare parts By prioritising durability, manufacturers can extend the lifespan of electronic products, reduce the frequency of replacements, and ultimately decrease the amount of e-waste generated. Using Sustainable Materials in Manufacturing Processes: Greener Options Image Source: MDPI – Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition. 2013. The materials used in electronics manufacture have a significant environmental impact. Traditional materials, such as plastics and certain metals, are difficult to recycle and may contain harmful compounds. Manufacturers may reduce their goods’ environmental impact and improve e-waste recycling by using sustainable and recyclable materials. Sustainable Materials Gaining Traction in Electronics Bioplastics: Derived from renewable sources like corn or sugarcane, bioplastics offer a greener alternative to traditional petroleum-based plastics. Recycled Metals: Reusing metals reduces the need for new mining operations, thus conserving valuable resources. Conflict-Free Minerals: Ensuring minerals are sourced ethically and responsibly helps to prevent human rights abuses. The use of sustainable materials benefits both the environment and enterprises. Reduced Environmental Impact: Eco-friendly materials are less hazardous to the environment during manufacturing, usage, and disposal. Improved Brand Image: As consumers become more aware of the importance of sustainability, organisations that use environmentally friendly products can improve their brand reputation. Successful examples of such initiatives include: Apple’s Renew program, which offers free recycling or trade-in for eligible devices. Dell’s Reconnect program, which partners with Goodwill to provide convenient e-waste drop-off locations. HP’s Planet Partners program, which offers a range of recycling and take-back options for consumers and businesses. Extended Producer Responsibility and Circular Economy Practices: Rethinking the Linear Model Extended Producer Responsibility (EPR) is a strategy that takes producers’ obligation beyond the moment of sale, holding them accountable for the environmental impact of their products throughout their full lifecycle, from disposal to recycling. By including the financial cost of end-of-life management in their operations, EPR motivates manufacturers to prioritise sustainable product design and actively contribute to the development of recycling infrastructure. The circular economy takes this concept further, aiming to eliminate waste and keep resources in use for as long as possible. Manufacturers can embrace circular economy practices by: Designing for Disassembly and Recycling: Creating products that are easy to take apart and recycle at the end of their life. Offering Repair and Upgrade Services: Extending the lifespan of products through repair and upgrade options. Using Recycled Materials: Incorporating recycled materials into new products, reducing the need for virgin resources. Key Roles of Manufacturers in the E-Waste (Management) Amendment Rules, 2024 Increased Extended Producer Responsibility (EPR). Increased collection targets: Manufacturers now have a larger obligation to collect and recycle e-waste generated by their products. This pushes them to create items that are easier to recycle and to set up effective collection and recycling systems. EPR Certificate Exchange Platform Flexibility and Efficiency: The government’s potential establishment of a platform for exchanging or transferring EPR certificates provides manufacturers with more flexibility in meeting their EPR obligations. Market-Driven Solutions: This could lead to a more market-driven approach to e-waste management practices, where manufacturers can buy or sell certificates based on their recycling performance. Relaxation of Reporting Deadlines (Conditional) Flexibility in Compliance: The government has the authority to extend reporting deadlines under specific circumstances, offering some relief to manufacturers facing challenges in meeting their EPR targets.